Fast track for NPI programmes

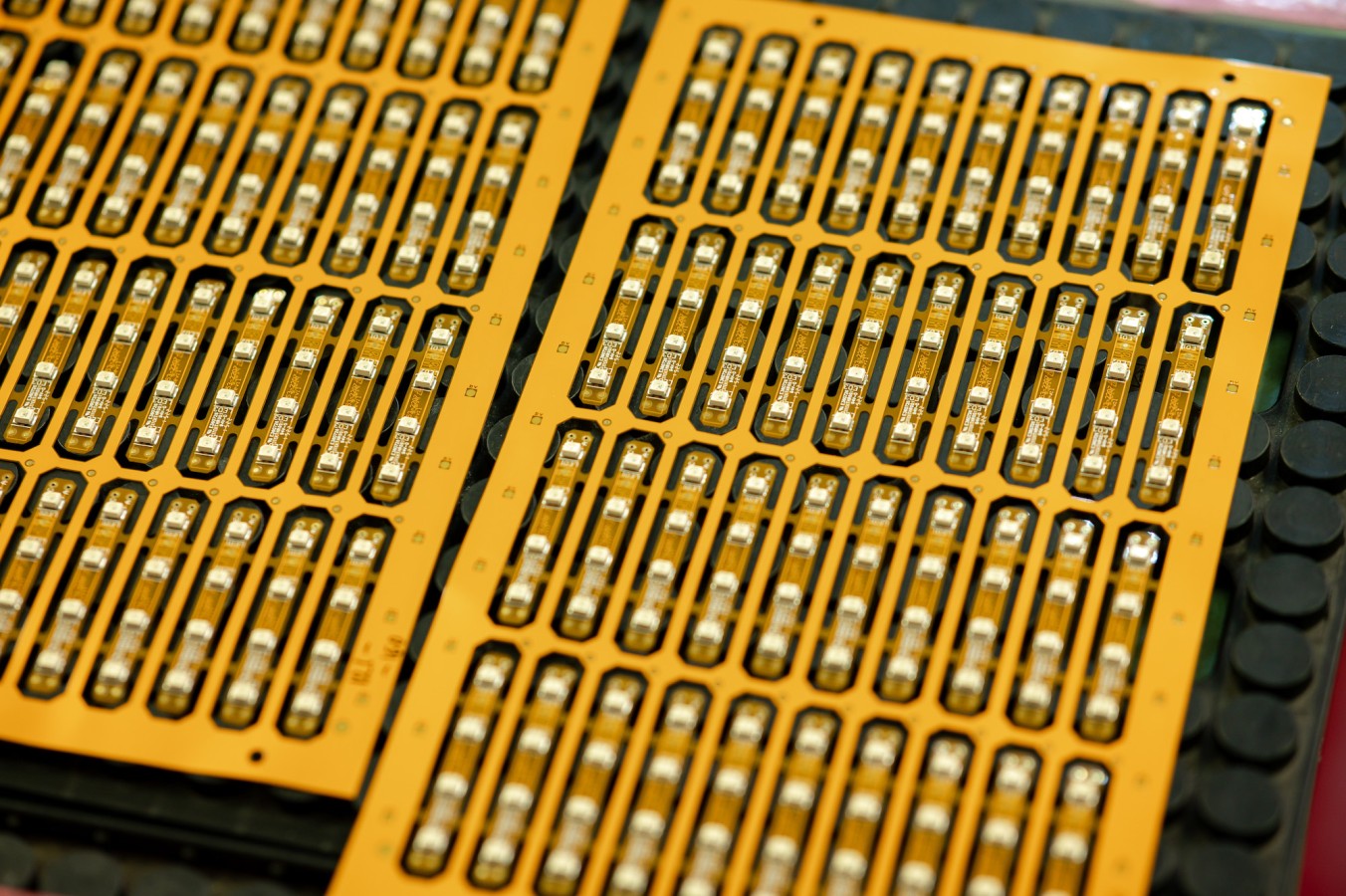

Our fast track new product introduction (NPI) service has become a key element in customers’ NPI programmes.

Producing a fully functioning, quality-production assembly, means you can carry out trials to test your new product’s functionality, with your customers sure in the knowledge the quality of manufacture meets your requirements.